Made in USA smartphones set the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. The rise of domestic smartphone manufacturing is a compelling tale of economic revival, technological innovation, and a renewed sense of American pride.

This resurgence is driven by a confluence of factors, including a desire for greater economic security, concerns about supply chain vulnerabilities, and a growing consumer preference for products made in the United States. The landscape is evolving with new players emerging and established companies re-evaluating their manufacturing strategies.

The Rise of “Made in USA” Smartphones

The American smartphone market, once dominated by foreign manufacturers, is witnessing a resurgence of “Made in USA” devices. This shift reflects a growing demand for domestically produced goods, driven by factors ranging from economic patriotism to concerns about supply chain security.

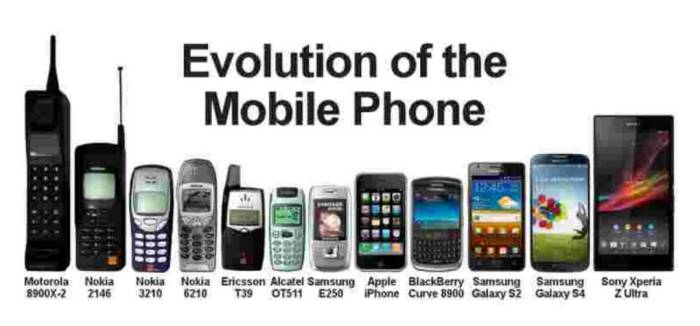

Historical Context of American Smartphone Manufacturing

The early days of smartphone development were marked by significant American contributions. Companies like IBM, Motorola, and Palm pioneered the mobile phone industry, with the first smartphones emerging in the late 1990s. However, the rise of Android and the dominance of Asian manufacturers, particularly Samsung and Huawei, led to a decline in American smartphone production.

Factors Driving the Resurgence of “Made in USA” Smartphones, Made in usa smartphone

Several factors are driving the resurgence of “Made in USA” smartphones.

- Economic Patriotism: Consumers are increasingly seeking to support American jobs and businesses, leading to a preference for domestically produced goods.

- Supply Chain Security: Concerns about reliance on foreign manufacturers for critical technologies have spurred efforts to bolster domestic production. The COVID-19 pandemic highlighted the vulnerability of global supply chains, further emphasizing the need for a more resilient manufacturing ecosystem.

- Government Incentives: Federal and state governments have introduced initiatives to encourage domestic manufacturing, including tax breaks, grants, and research funding.

- Technological Innovation: The United States continues to be a leader in semiconductor technology, which is a key component of smartphones. This technological advantage is attracting manufacturers to establish production facilities in the US.

Key Players and Initiatives Promoting Domestic Production

Several companies and organizations are actively promoting the production of “Made in USA” smartphones.

- Foxconn: The Taiwanese electronics giant, a major manufacturer for Apple and other brands, has established a factory in Wisconsin, USA, producing smartphones and other electronic devices. This facility signifies a significant investment in domestic manufacturing, contributing to the growth of the “Made in USA” smartphone sector.

- Motorola: The American company, once a pioneer in mobile phones, has re-entered the smartphone market with a focus on “Made in USA” devices. Motorola’s commitment to domestic production is a testament to the growing demand for American-made products.

- The American Made Challenges: The White House’s “American Made Challenges” program encourages innovation and domestic manufacturing in various sectors, including smartphones. The program provides funding and support to businesses developing cutting-edge technologies and manufacturing processes.

- The Manufacturing USA Institutes: These public-private partnerships focus on advancing manufacturing capabilities in key industries, including electronics and semiconductors. The Institutes provide resources and expertise to companies seeking to establish or expand domestic production.

Economic and Social Impacts

Bringing smartphone manufacturing back to the US has the potential to create a ripple effect throughout the economy, generating jobs, boosting local communities, and strengthening the nation’s technological prowess. This shift represents a significant opportunity to revitalize American manufacturing and create a more sustainable and resilient supply chain.

Economic Benefits

The economic benefits of manufacturing smartphones in the US are substantial. By bringing production back home, the US can capture a larger share of the value chain, creating jobs and generating economic activity. This can lead to a more robust and diversified economy, less reliant on foreign manufacturing.

- Job Creation: The manufacturing of smartphones involves a complex process that requires a skilled workforce across various disciplines, from engineering and design to assembly and quality control. Bringing this production back to the US would create thousands of new jobs, not only in manufacturing but also in supporting industries like logistics, transportation, and research and development.

- Increased Economic Activity: The manufacturing of smartphones involves a complex supply chain that extends beyond the factory floor. The production process requires raw materials, components, and services, which can boost economic activity in local communities and across the country. For example, the production of smartphones requires a wide range of materials, such as glass, aluminum, and semiconductors, which can be sourced from US-based suppliers.

- Tax Revenue: Increased economic activity and job creation would generate higher tax revenue for local, state, and federal governments. This revenue can be used to fund essential public services, such as education, healthcare, and infrastructure, further contributing to economic growth and community development.

Impact on Local Communities

Bringing smartphone manufacturing back to the US can have a significant positive impact on local communities. By creating jobs and boosting economic activity, it can revitalize struggling areas and create opportunities for residents.

- Economic Revitalization: The creation of new jobs and the increased economic activity associated with smartphone manufacturing can revitalize local economies, particularly in areas that have been struggling with high unemployment rates. The presence of a major manufacturing facility can attract other businesses and investment, further boosting the local economy.

- Community Development: The influx of new jobs and investment can lead to improvements in local infrastructure, housing, and education. This can create a more attractive environment for residents and businesses, leading to a virtuous cycle of growth and development.

- Increased Tax Revenue: The increased economic activity associated with smartphone manufacturing can lead to higher tax revenue for local governments. This revenue can be used to fund essential public services, such as schools, libraries, and parks, improving the quality of life for residents.

Social Implications

The decision to support American manufacturing has broader social implications, fostering a sense of national pride and contributing to a more sustainable and resilient economy.

- National Pride: Bringing smartphone manufacturing back to the US can foster a sense of national pride and patriotism. It can demonstrate that the US is capable of competing on a global stage in advanced manufacturing and innovation. This can inspire a new generation of workers and entrepreneurs to pursue careers in STEM fields, further strengthening the US economy.

- Economic Security: By reducing reliance on foreign manufacturing, the US can become more resilient to global economic shocks and disruptions. This can lead to greater economic security for American workers and businesses.

- Environmental Sustainability: By manufacturing smartphones in the US, companies can reduce their carbon footprint by minimizing the transportation distances and associated emissions. This can contribute to a more sustainable and environmentally friendly supply chain.

Technological Considerations

The rise of “Made in USA” smartphones presents a unique set of technological challenges and opportunities. This section delves into the comparison of technological capabilities between US-made and foreign-manufactured smartphones, analyzes the intricacies of domestic development and production, and explores the pivotal role of innovation and research in fostering a competitive “Made in USA” smartphone market.

Comparison of Technological Capabilities

The technological landscape of smartphones is constantly evolving, with innovations in hardware, software, and connectivity pushing the boundaries of what’s possible. Comparing the technological capabilities of US-made smartphones with those manufactured elsewhere reveals both similarities and differences.

- Hardware: US-made smartphones generally prioritize high-quality components and robust build quality, often featuring advanced processors, high-resolution displays, and premium materials. For example, Apple’s iPhone, manufactured in the US, is known for its powerful A-series processors and durable glass construction. In contrast, some smartphones manufactured in other countries, like China, may prioritize affordability and focus on providing competitive features at lower price points.

- Software: US-based companies like Apple and Google have a significant influence on the global smartphone software ecosystem. Their operating systems, iOS and Android, respectively, dominate the market. While other countries are developing their own mobile operating systems, the US remains a leader in software innovation and development.

- Connectivity: The US has played a crucial role in developing and implementing advanced cellular technologies like 5G. US-made smartphones often integrate the latest connectivity standards, enabling faster data speeds and improved network performance. While other countries are also investing in 5G infrastructure, the US remains a frontrunner in this area.

Challenges and Opportunities in Domestic Development and Production

Developing and producing advanced smartphone technologies domestically presents both challenges and opportunities.

- Manufacturing Costs: The US faces higher labor costs compared to some other manufacturing hubs, making it more expensive to produce smartphones domestically. This can impact the affordability of US-made devices and create challenges in competing with lower-priced products from overseas.

- Supply Chain Challenges: The smartphone industry relies on a complex global supply chain, with many components sourced from different countries. Establishing a fully domestic supply chain for smartphones would require significant investment and collaboration across various industries.

- Talent Acquisition: The US needs to attract and retain a skilled workforce to support the development and production of advanced smartphone technologies. This involves investing in education and training programs to cultivate talent in areas like engineering, software development, and manufacturing.

- Innovation Ecosystem: Fostering a robust innovation ecosystem is crucial for the success of a “Made in USA” smartphone market. This involves supporting research and development, encouraging collaboration between academia, industry, and government, and creating an environment that encourages entrepreneurship and innovation.

Role of Innovation and Research

Innovation and research are fundamental to the development of competitive smartphone technologies.

- Emerging Technologies: Research and development in areas like artificial intelligence (AI), augmented reality (AR), and advanced materials are essential for pushing the boundaries of smartphone capabilities. US-based companies and research institutions are actively exploring these frontiers, aiming to develop groundbreaking technologies that will redefine the smartphone experience.

- University-Industry Partnerships: Collaborations between universities and industry are vital for translating research findings into practical applications. These partnerships can foster a pipeline of talent, accelerate innovation, and ensure that the US remains at the forefront of smartphone technology.

- Government Support: Government funding and policies can play a crucial role in supporting innovation and research in the smartphone industry. This includes investments in research grants, tax incentives for companies engaged in R&D, and initiatives to promote STEM education.

Challenges and Opportunities

The “Made in USA” smartphone industry faces significant challenges, but also holds considerable potential for growth and innovation. This section explores the key obstacles, the potential for government support, and the opportunities for collaboration within the industry.

Challenges

The “Made in USA” smartphone industry faces several challenges:

- High Manufacturing Costs: The cost of labor, materials, and infrastructure in the United States is significantly higher than in countries like China and Vietnam, where most smartphones are currently manufactured. This makes it difficult for American companies to compete on price with foreign manufacturers.

- Supply Chain Disruptions: The global supply chain for smartphone components is complex and interconnected. Disruptions to this chain, such as natural disasters, political instability, or trade wars, can significantly impact the production and availability of smartphones in the United States.

- Lack of Skilled Labor: The United States faces a shortage of skilled workers in fields like manufacturing, engineering, and software development. This shortage makes it difficult for American companies to find and retain the talent needed to build and maintain a domestic smartphone industry.

- Technological Dependence: The United States relies heavily on foreign companies for key smartphone technologies, such as chipsets, displays, and software. This dependence makes the industry vulnerable to foreign competition and geopolitical pressures.

Government Support and Policy Initiatives

The potential for government support and policy initiatives to promote domestic production is substantial. These initiatives could include:

- Tax Incentives: Offering tax breaks and subsidies to companies that manufacture smartphones in the United States could help to reduce production costs and make domestic manufacturing more competitive.

- Research and Development Funding: Investing in research and development for advanced smartphone technologies could help to create new innovations and boost the competitiveness of the “Made in USA” industry.

- Trade Policies: Implementing trade policies that protect American manufacturers from unfair competition from foreign companies could help to level the playing field and encourage domestic production.

- Education and Training Programs: Investing in education and training programs to develop a skilled workforce in manufacturing, engineering, and software development could help to address the labor shortage and build a strong foundation for the “Made in USA” smartphone industry.

Collaboration and Partnerships

Collaboration and partnerships within the industry can play a crucial role in overcoming challenges and fostering innovation.

- Joint Ventures: American companies could form joint ventures with foreign companies to share expertise, technology, and resources, reducing production costs and enhancing competitiveness.

- Industry Consortia: Establishing industry consortia to address common challenges, such as supply chain disruptions and labor shortages, could lead to collective solutions and foster innovation.

- University Partnerships: Collaborating with universities to conduct research, develop new technologies, and train skilled workers could help to create a strong pipeline of talent for the “Made in USA” smartphone industry.

Sustainability and Environmental Impact

The manufacturing and use of smartphones have a significant environmental footprint, and the shift towards “Made in USA” smartphones presents both opportunities and challenges for sustainability. This section delves into the environmental impact of domestic smartphone production, explores the potential for sustainable practices and responsible sourcing, and examines the role of “Made in USA” smartphones in promoting a circular economy.

Environmental Impact of Domestic Smartphone Manufacturing

The environmental impact of smartphone manufacturing is multifaceted and includes the extraction of raw materials, energy consumption during production, and the disposal of electronic waste. While manufacturing smartphones in the US might offer some environmental benefits, it is crucial to analyze the complete lifecycle impact.

- Raw Material Extraction: Sourcing raw materials like rare earth minerals, lithium, and cobalt often involves environmentally damaging mining practices in countries with weaker environmental regulations. Domestic production could potentially reduce the environmental impact of raw material extraction if US mines are subject to stricter environmental standards and sustainable mining practices are implemented.

- Energy Consumption: Manufacturing smartphones is energy-intensive, and the environmental impact depends on the energy source used. If US manufacturing facilities rely heavily on renewable energy sources, it could contribute to a lower carbon footprint compared to regions with a high reliance on fossil fuels. However, the energy efficiency of manufacturing processes and the transportation of components remain crucial factors.

- E-Waste Generation: Smartphones have a short lifespan, leading to a growing e-waste problem. Responsible recycling and disposal of e-waste are essential for mitigating environmental harm. While domestic production could facilitate better e-waste management, it’s crucial to ensure proper collection, recycling, and disposal processes are in place to prevent harmful materials from ending up in landfills.

Sustainable Practices and Responsible Sourcing

The US smartphone industry has the potential to adopt sustainable practices and responsible sourcing strategies to minimize its environmental impact.

- Closed-Loop Manufacturing: Implementing closed-loop manufacturing processes involves reusing and recycling materials, reducing the need for virgin resources. This approach can significantly reduce the environmental impact of raw material extraction and minimize waste generation.

- Renewable Energy: Shifting to renewable energy sources for manufacturing facilities is crucial to reduce greenhouse gas emissions. Companies can invest in solar, wind, or geothermal energy to power their operations, contributing to a cleaner energy mix.

- Responsible Sourcing: Ensuring the responsible sourcing of raw materials, particularly those with high environmental and social risks, is essential. This involves working with suppliers who adhere to ethical and sustainable practices, including fair labor standards and environmental compliance.

Promoting a Circular Economy

“Made in USA” smartphones can play a significant role in promoting a circular economy, a model that aims to minimize waste and maximize resource utilization.

- Extended Producer Responsibility: Domestic manufacturers could take greater responsibility for the entire lifecycle of their products, including end-of-life management. This involves providing recycling options, offering repair services, and ensuring the safe disposal of electronic waste.

- Modular Design: Designing smartphones with modular components allows for easy repair and upgrades, extending the lifespan of devices and reducing e-waste. This approach also promotes the reuse of components and reduces the need for new materials.

- Product Durability: Building durable smartphones that withstand wear and tear and can be easily repaired reduces the need for frequent replacements, contributing to a more sustainable consumption pattern.

Future of “Made in USA” Smartphones

The “Made in USA” smartphone industry is at a pivotal juncture, poised for potential growth and innovation. While challenges remain, the industry’s future trajectory hinges on a confluence of factors, including government policies, technological advancements, and consumer preferences.

Factors Shaping the Future of Domestic Smartphone Manufacturing

The long-term success of “Made in USA” smartphones will be shaped by a complex interplay of factors. Here are some key aspects:

- Government Support: Continued government support through incentives, tax breaks, and investment in research and development will be crucial to fostering a competitive domestic manufacturing ecosystem. For example, the CHIPS and Science Act of 2022 aims to boost domestic semiconductor production, which could indirectly benefit the smartphone industry.

- Technological Advancements: The ability to compete with global leaders in smartphone technology, such as advanced processors, camera systems, and battery technology, will be paramount. Investments in research and development, collaborations with universities and tech companies, and attracting skilled talent are essential.

- Consumer Demand: Consumers are increasingly interested in supporting domestic products, particularly those with a focus on sustainability and ethical sourcing. However, “Made in USA” smartphones will need to compete on price, features, and brand recognition to capture a significant market share.

- Supply Chain Resilience: Building a robust and resilient supply chain for components and manufacturing is crucial. This involves sourcing materials domestically whenever possible, establishing strategic partnerships with domestic suppliers, and reducing reliance on foreign manufacturers.

- Innovation and Differentiation: To stand out in a crowded market, “Made in USA” smartphone manufacturers will need to focus on innovation and differentiation. This could involve developing unique features, focusing on specific market segments, or offering tailored software and services.

Case Studies: Made In Usa Smartphone

The rise of “Made in USA” smartphones has been driven by a confluence of factors, including a growing consumer demand for domestically produced goods, government initiatives promoting domestic manufacturing, and the emergence of innovative companies focused on American production. Examining successful examples of “Made in USA” smartphones provides valuable insights into the challenges and opportunities associated with this trend.

Examples of Successful “Made in USA” Smartphones

These case studies showcase the diverse approaches and achievements of companies committed to manufacturing smartphones in the United States.

| Brand | Model | Key Features | Notable Achievements |

|---|---|---|---|

| Red Hydrogen One | Hydrogen One | 4-view 3D display, holographic content, modular design | Pioneered the development of a holographic smartphone, raised over $1 million on Kickstarter |

| Fairphone | Fairphone 4 | Modular design, repairable components, ethical sourcing of materials | Recognized for its commitment to sustainability and ethical manufacturing practices |

| Motorola | Motorola Edge+ (2023) | High-end specifications, 5G connectivity, robust camera system | One of the few flagship smartphones manufactured in the United States |

| Unihertz | Jelly 2 | Compact design, long battery life, affordable price | Targeted a niche market with a unique and functional smartphone |

Epilogue

The future of “Made in USA” smartphones is bright, with a potential for growth fueled by technological advancements, increased consumer demand, and a renewed focus on domestic manufacturing. The challenges are real, but the opportunities are even greater. As we move forward, the story of “Made in USA” smartphones is one of innovation, resilience, and the enduring power of American ingenuity.

While “Made in USA” smartphones are gaining popularity, one of the key features consumers look for is a long-lasting battery. If you’re searching for a phone with impressive battery life, consider exploring the options available in the smartphone with longer battery life category.

This could be a crucial factor when choosing a US-made phone, as you want to ensure you’re getting the best value for your investment.

Informatif Berita Informatif Terbaru

Informatif Berita Informatif Terbaru